Vacuum Thermoforming

Vacuum thermoforming is the process of heating a plastic sheet and bending it on a mold. With cooling, the piece permanently retains the set shape.

Our experience:

We offer complete design and production of automotive and machine parts, advertising products, and others. We have extensive experience in combining high-quality printing with thermoformed elements. We also produce molds and finish the workpiece with a cut along a 5D contour with extreme precision.

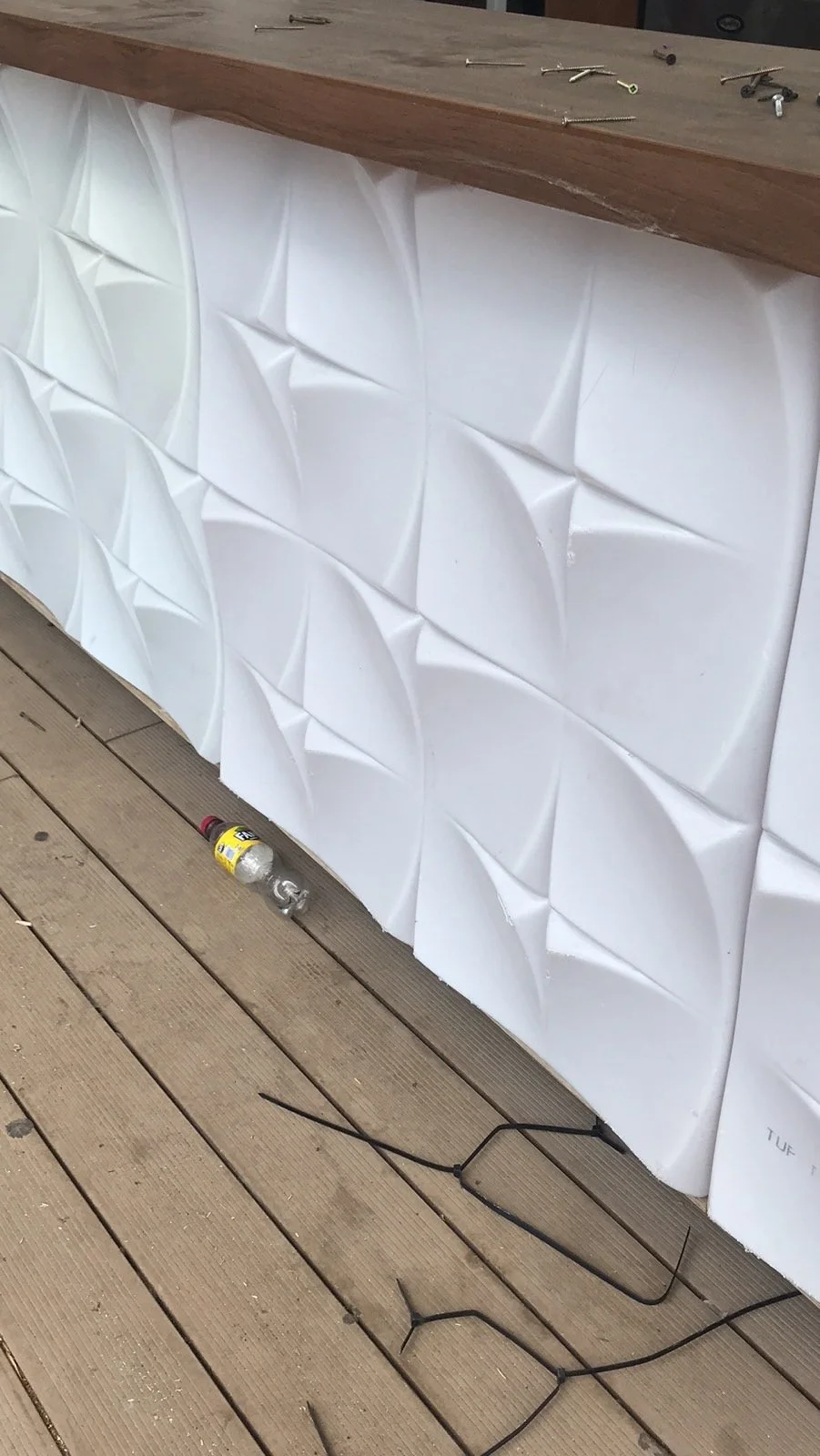

Vacuum Thermoforming

-

Vacuum thermoforming of parts of different types of transparent and colored plastics. The dimensions and materials are shown below in 'technical specifications.

Vacuum thermoforming + Printing

-

The inks we use do not lose their brightness and density when heated and bent. The printed detail also allows additional backlight.

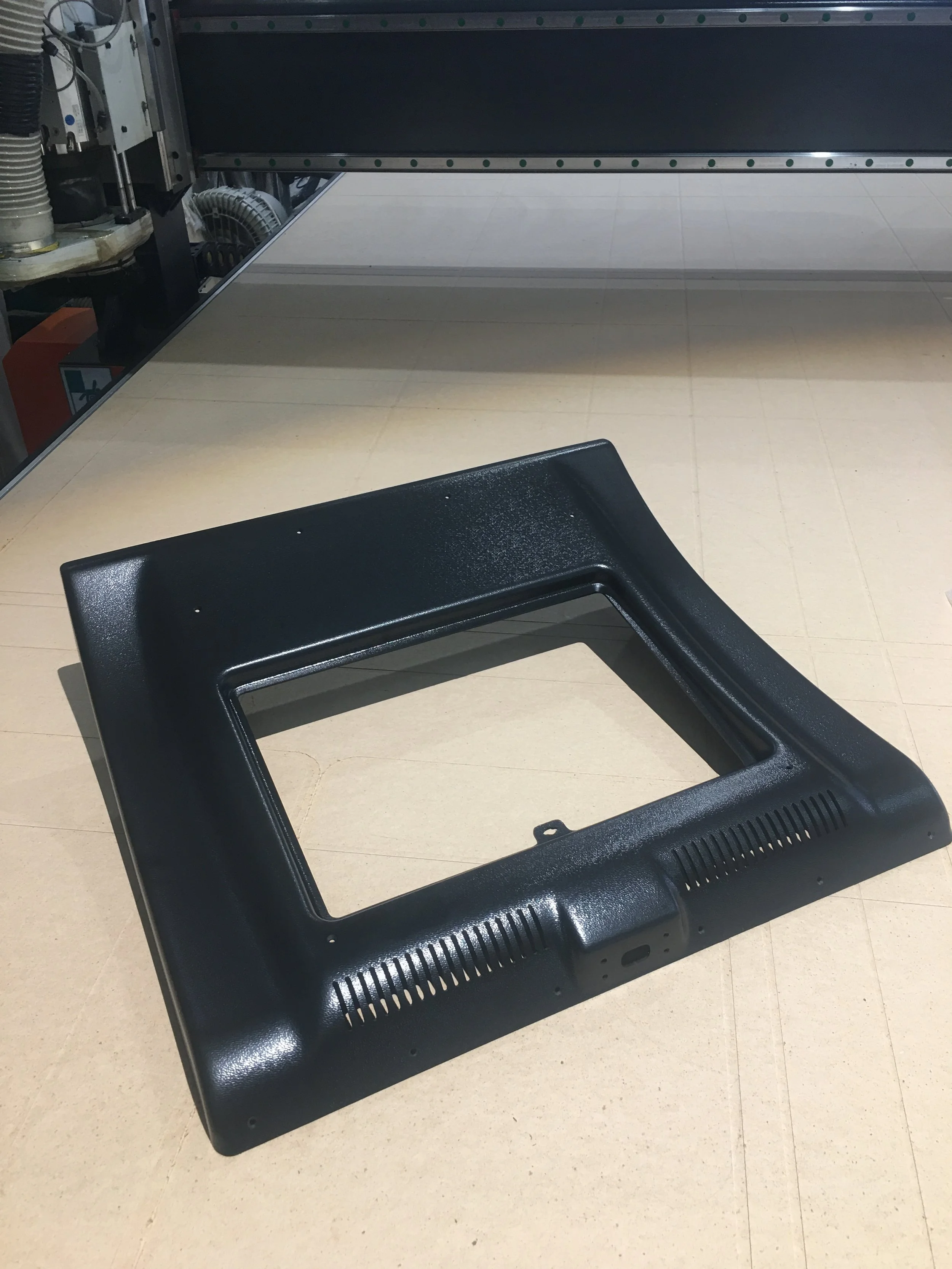

Vacuum Thermoforming + 5D Contour Cutting

-

We use high-quality robots to cut holes in bent details. The cut is on a 5D contour and is distinguished by exceptional precision.

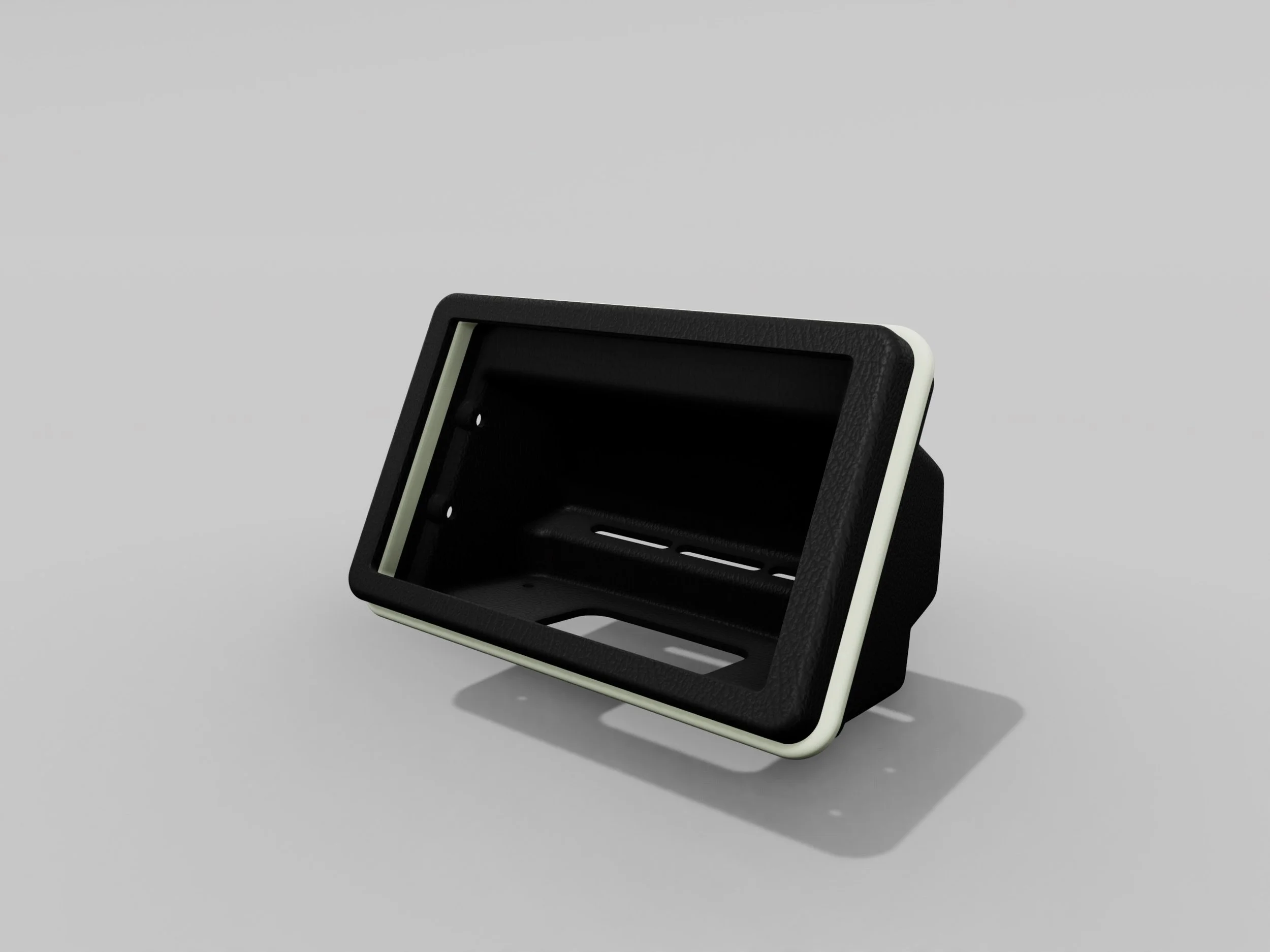

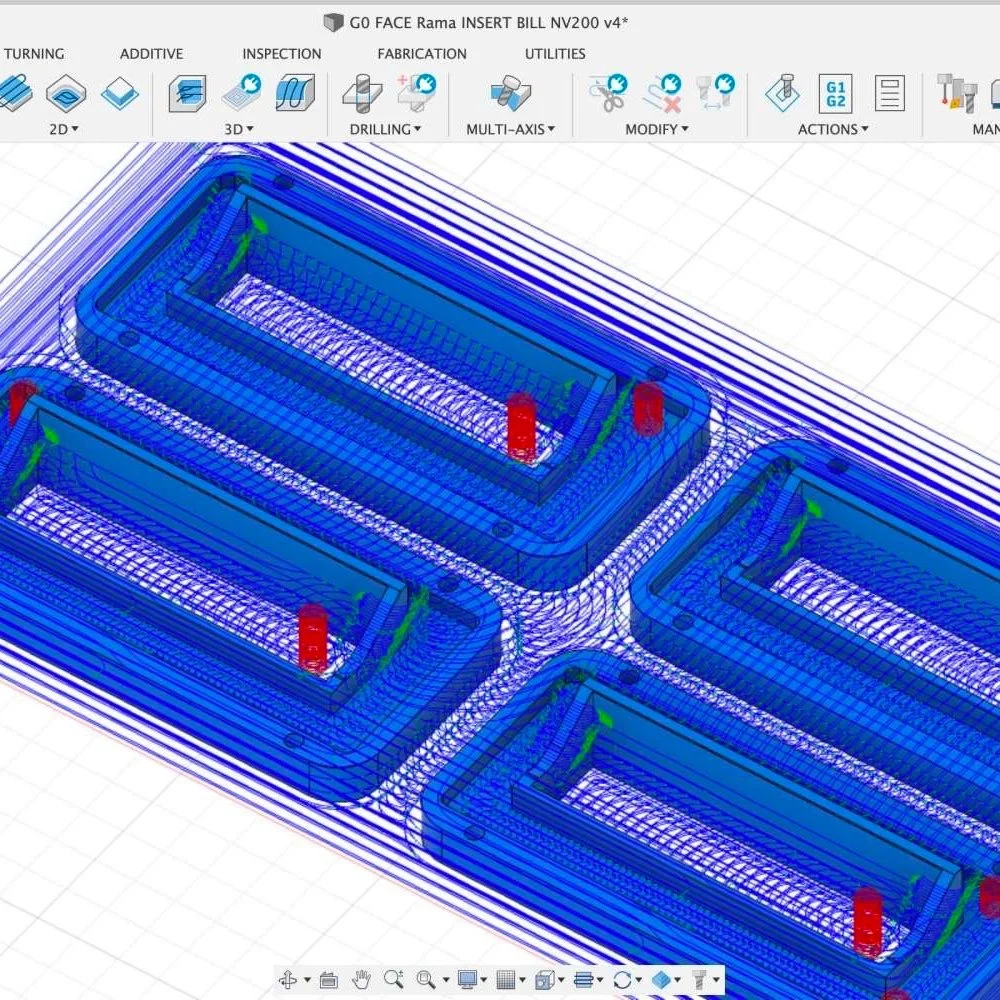

Design of a 3D Model

-

Our specialists are experienced in the design of 3D models and visualizations of complex details.

Design of a 3D Mold Model

-

In addition to the design of the workpiece, we create a 3D version of the corresponding mold.

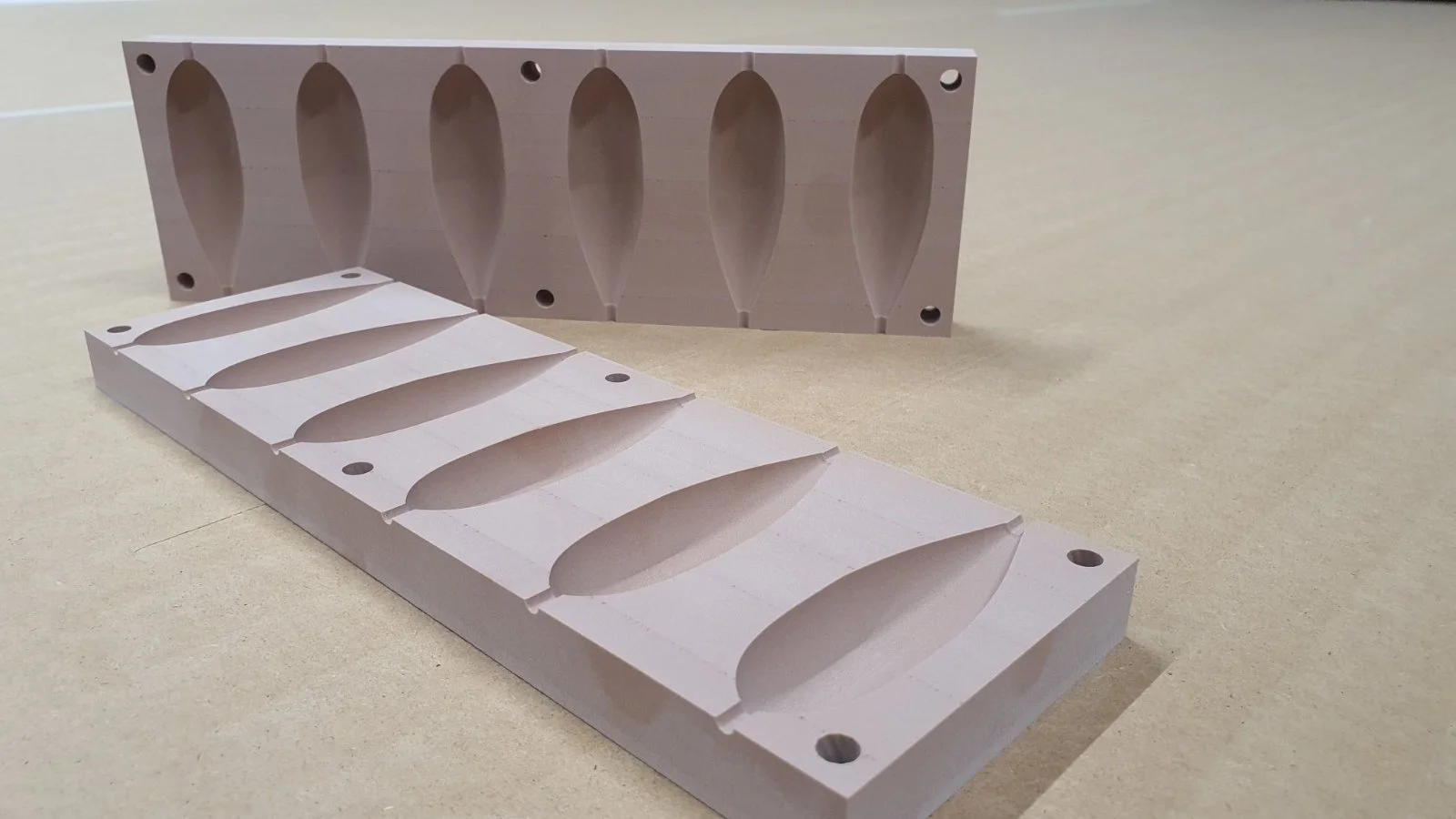

Mold Production

-

We make all the necessary molds, that can also be used repeatedly for repetitive orders.

Technical specifications:

Moulded area: 1460 x 960mm / 57.5 x 37.8"

Sheet size: 1500 x 1000mm / 59 x 39.4"

Maximum bend depth: 600mm / 23.5"

Maximum material thickness: 6mm / 0.25"

Most commonly molded materials:

ABS

PETG

HDPE

HIPS/PETG